Not all Greases are Compatible

Most plant maintenance personnel try to standardize on one lubricant wherever possible to simplify maintenance operations. Great care needs to be taken in ensuring the grease is compatible with that supplied with the motor originally.

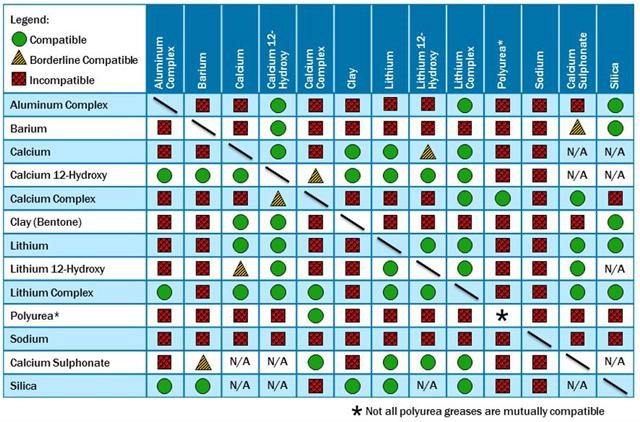

In that there are many types of industrial grade greases, great care must also be taken that the thickening agents are compatible. Separation of the thickener and the oil, which provides the necessary lubrication, can lead to premature failures of the motor bearings. In addition, issues may exist this:

- Base Oil Compatibility

- Additive Compatibility

Some best practices for choosing a grease include:

- Carefully researching potential greases for long time operating characteristics such as elevated operating temperatures, as well as exposure to chemicals, moisture, and dust present in the surrounding environment.

- Check for compatibility with existing lubricants used by the motor manufacturer or rewind shop.

- Removing a bearing component and completely removing previous lubricant when a potential compatibility issue exists.

The technical specialists at Flolo Corporation have extensive knowledge of Lubricants and their proper use as well as best relubrication practices. This knowledge comes from working with a wide variety of motor as well as bearing suppliers. In addition, the technical specialists at Flolo have worked extensively with a wide variety of end users and OEMs across numerous industries in analyzing lubricant related failures as well as other types of bearing failure issues.