Solutions at the Drive and Motor cables

Part 2 of 2 part series on Motor Bearing Current Failures

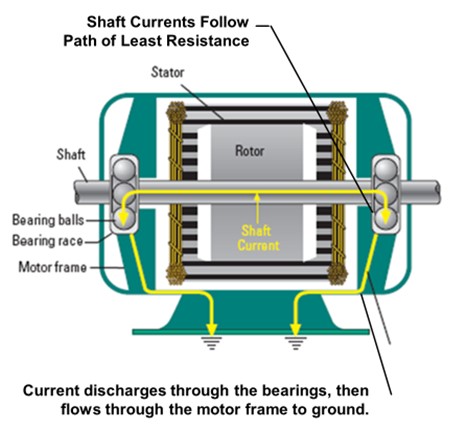

As discussed in part 1, increasingly motors are operated on variable frequency drives. This often results in premature bearing failure due to bearing currents.

These currents passing through the bearings can lead to damage in the form of heavy frosting and/or fluting.

As the condition worsens, this will usually result in audible noise coming from the bearings and eventual bearing failure.

Note: Bearings in directly coupled components, such as pumps and gearboxes, can also experience the same type of failure.

Solutions at the VF

- Add a dv/dt sine filter at the output of the VFD. This reduces the magnitude of the dv/dt pulse by a factor of 3. This is especially important on longer cable runs between the VFD and motor.

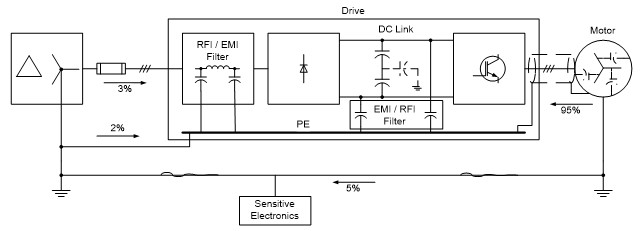

2. Provide proper grounding between:

- VFD

- Motor

- Drive Load

Use motor cables specifically designed for use with a VFD. These incorporate 3 copper ground conductors – which provide a low impedance path for the common mode voltage to return to the drive. This is especially important on long cable runs between the VFD and motor.

The in-house technical specialist at The Flolo Corporation have extensive knowledge of bearing currents issues and solutions. Flolo is a certified AEGIS trained installer. Additional information on motor bearings currents are covered in extensive detail in classes available thru Flolo Tech. Please contact your Sales Representative for additional details.