What is a reasonable life expectancy and how do you optimize it.

Part 2 of a 3 part series on motor life expectancy

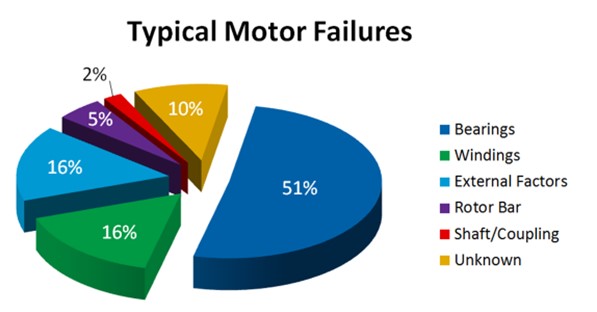

Many motors fail prematurely due to misapplication and this series will discuss ways to avoid these and optimize motor life. This avoids costly downtime an the expense of repair or replacement.

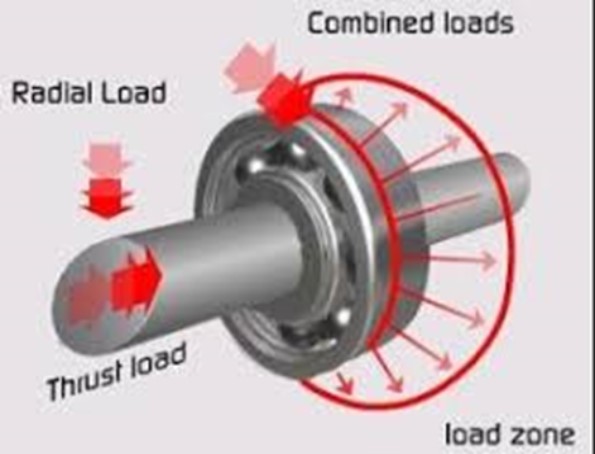

Failure of Bearings due to heavy side and/or thrust loading

These bearing failures are usually a result of over loading due to the connected load. Examples: belt and pulley (radial load); direct coupled axial fan (thrust load).

Solutions:

Utilizing a different type of bearing to handle the specific type of load the bearing is subjected to or modifying how the load is connected to the Motor.

Improper Bearing Lubrication

Improper lubrication intervals or amount of lubricant used can result in excess grease, inadequate grease or improper greasing procedure.

Surprisingly, over-lubrication is nearly as common as a lack of lubrication when it comes to bearing failures. The easiest way to prevent this is to follow the motor manufacturer’s guidelines for lubrication intervals as well as the proper amount of lubricant to add.

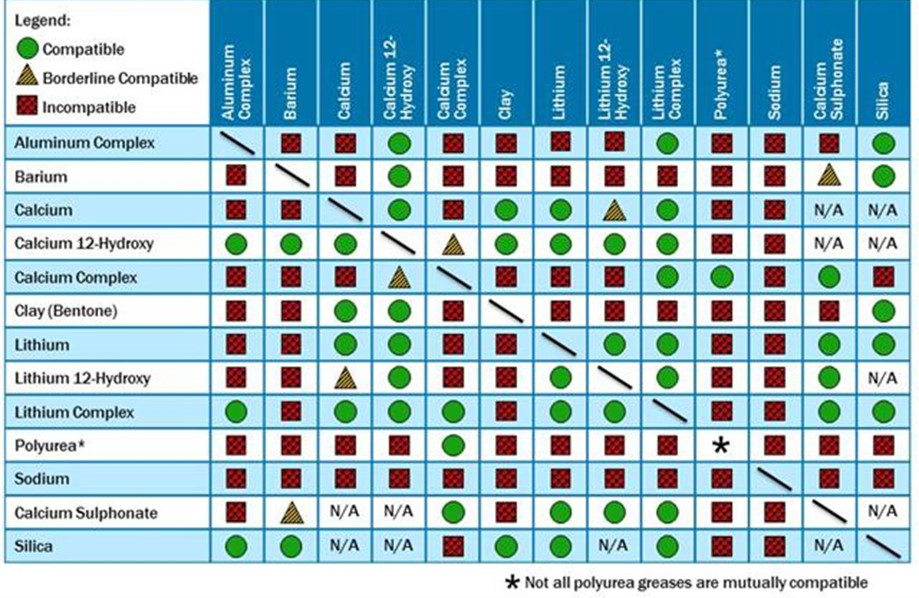

Mixing Incompatible Greases

The mixing of incompatible greases can result in excess lubricant thickening or oil drop out. Rapid lubricant failure is another common result when incompatible greases are mixed. This makes it critical to know what grease is used in your motor and make sure you re-lubricate only with a compatible grease (see table below).

Bearing Overheating

Bearing overheating can generally be attributed to excess winding temperature or inadequate motor cooling.

Excess temperature can result in annealing of the ring and ball material resulting in a loss of hardness and accelerate wear. Lubricant deterioration is also a result of bearing overheating.

The in-house technical specialist at Flolo have extensive knowledge of motor failures common across a broad range of industries and solutions that will maximize life expectancy in these demanding applications. Additional information on how to best optimize motor life are covered in extensive detail in classes available thru Flolo Tech. Please contact your Sales Representative for additional details.